15 years ago – or so – we had the good fortune to acquire waterfront property with a boat ramp. All it needed was a mooring to make things complete. Out came the copy of Chapman, and I built a mooring per the conventional wisdom. Something like this:

The anchor was a massive concrete hemisphere with an iron ring. The guy who delivered it on-site had attached a 6 foot log boom chain with a 1-1/2 inch shackle. I added a 3/4 inch swivel and 25 feet of 1/2 inch long-link chain. A 24 inch float with the chain passing through the middle, and a 5 foot pennant completed the setup.

The anchor was a massive concrete hemisphere with an iron ring. The guy who delivered it on-site had attached a 6 foot log boom chain with a 1-1/2 inch shackle. I added a 3/4 inch swivel and 25 feet of 1/2 inch long-link chain. A 24 inch float with the chain passing through the middle, and a 5 foot pennant completed the setup.

Just like the image above, and hell-for-stout. Not so much. It didn’t survive the first winter. The lower portion of the lighter chain was almost completely gone, and one of the swivel shackles had failed. The real excitement: the weight of chain kept the float in more-or-less the same place I had set it. I tied up my 21-footer, took the trailer off the truck, and built a camp fire. A little later noticed that the boat was gone! It had drifted almost onto the rocks by the time I got organized and retrieved it. Needless to say, that was it for the fishing weekend.

Here’s the deal: it isn’t the big waves, weight of the boat, passing logs, kelp, and other junk that tears up the mooring. It’s the constant little riffles. Whatever chain link is just at the bottom (where chain goes from lying flat to vertical) gets its galvanizing rubbed off. It rusts, and the rust gets rubbed off. The length of chain that’s subject to this (given the tidal range) dissolves pretty quickly.

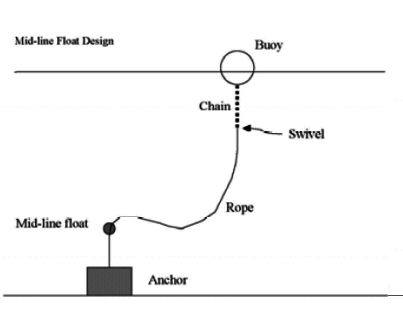

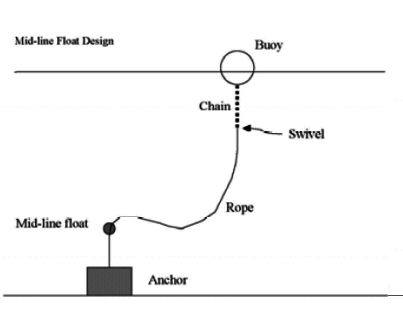

My solution (modified from a set-up a local diver described to me) is to use nylon rope instead of chain, and try to minimize motion in the places where metal must be used. That and use the heaviest parts available. The rope does the wiggling, and hopefully reduces the scuffing action on the metal.

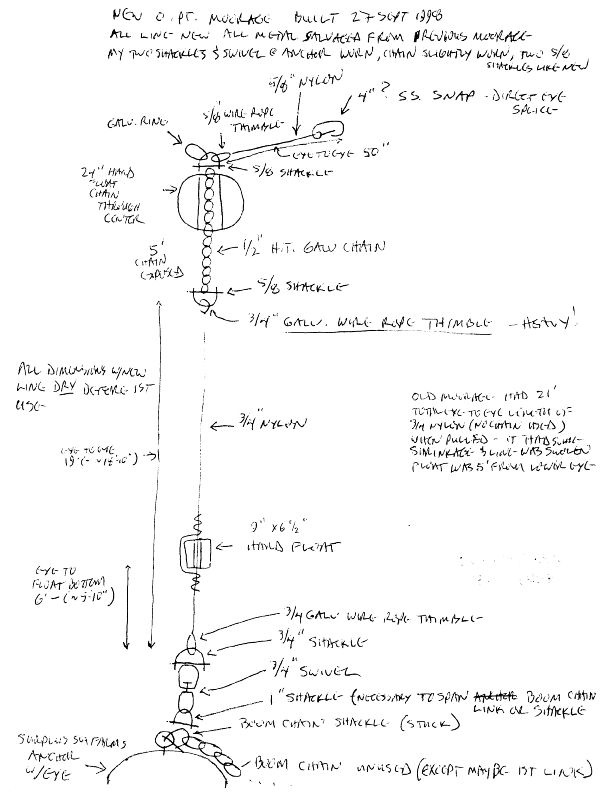

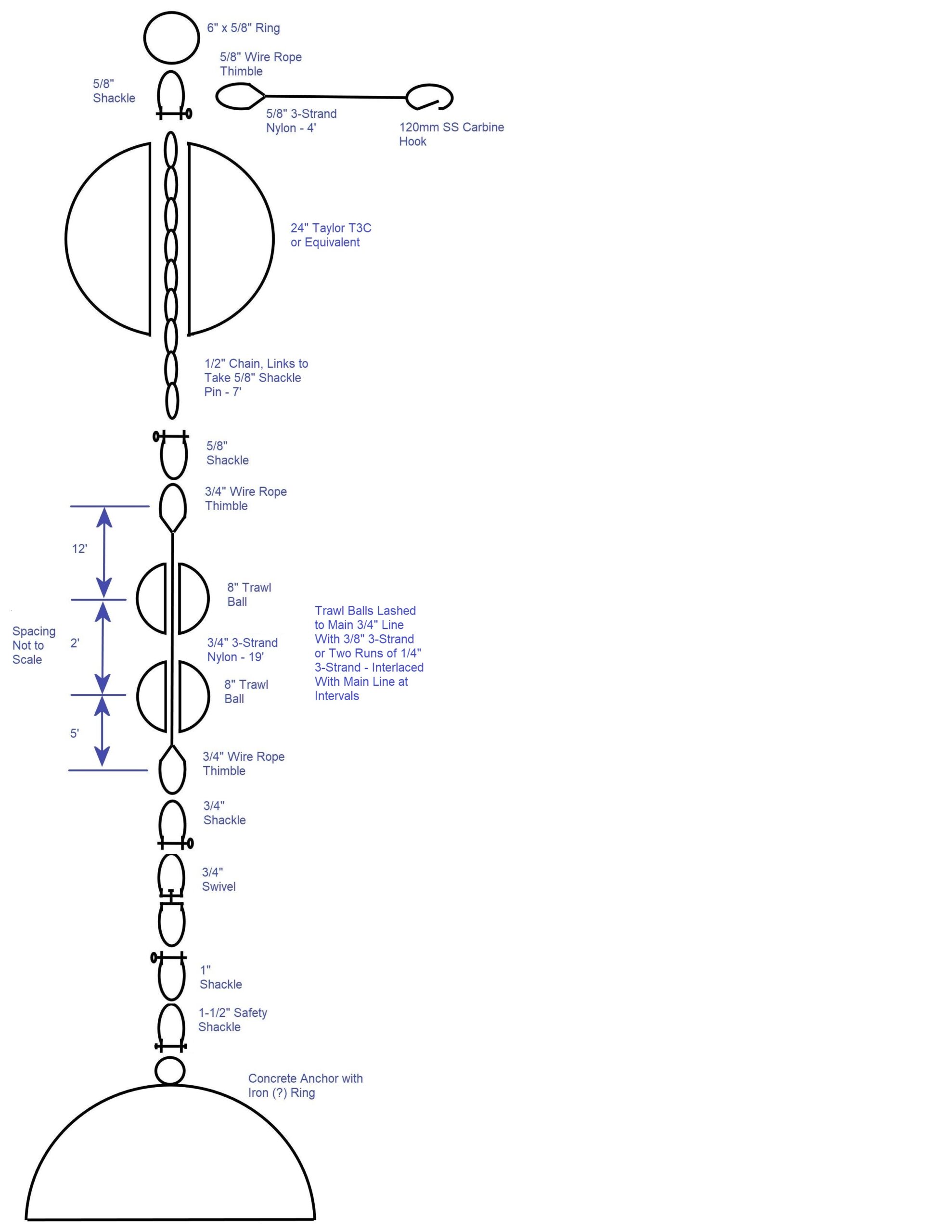

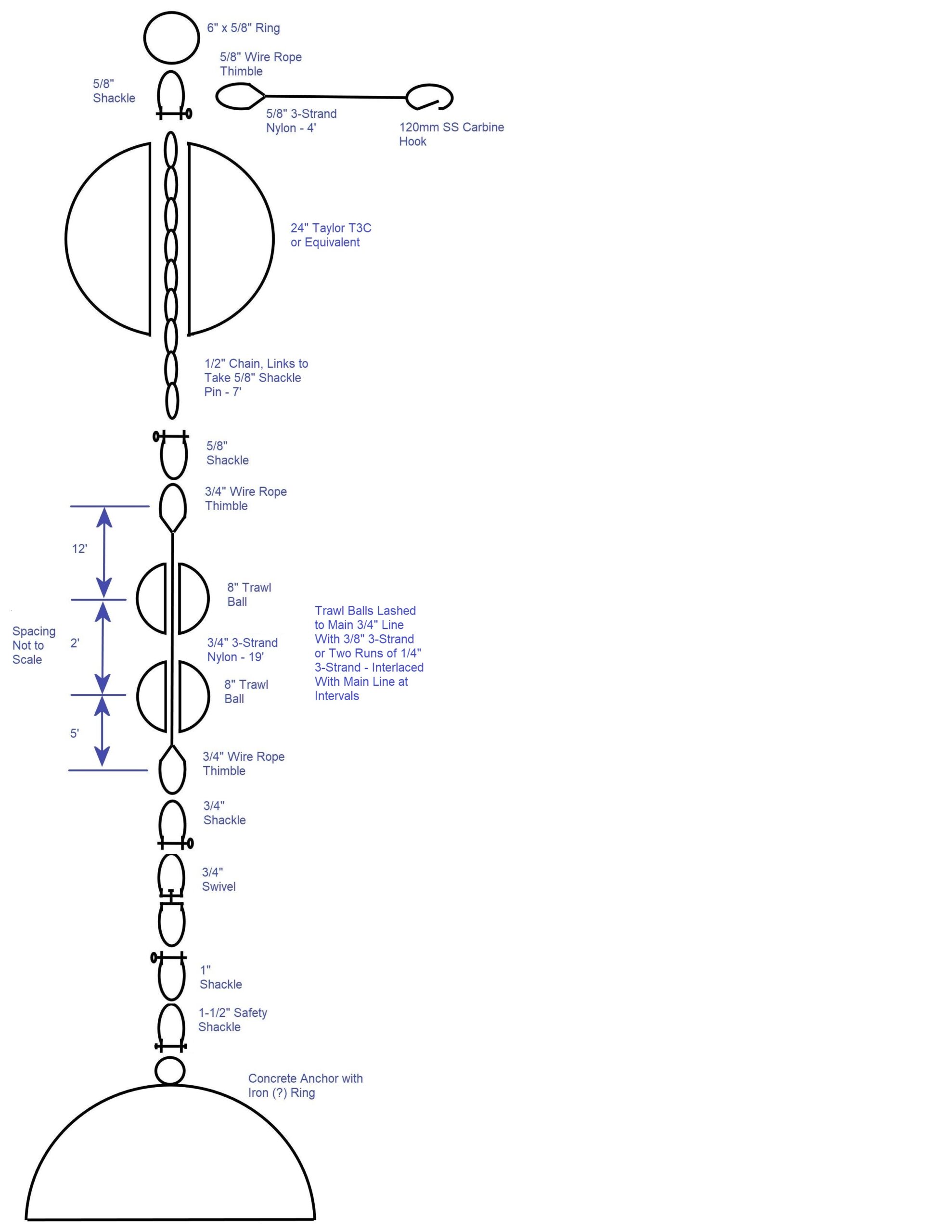

The setup, from the bottom up: anchor, 1-1/2 safety shackle (heavy enough to just lie flat most of the time so it doesn’t wear the anchor ring), 1 inch shackle (more or less vertical so it doesn’t wiggle much), 3/4 inch swivel (stands vertical), 3/4 inch shackle, 20 feet of 3/4 inch 3-strand nylon with 3/4 inch wire rope thimbles at each end, a mid-water float (trawl ball or similar to hold the swivel vertical and isolate the lower parts from the riffles) 6 feet from the bottom of the rope, 5/8 inch shackle, 7 feet of 1/2 inch long link chain through the float (the chain weight snubs some of the yank on the other parts), 24 inch float, 5/8 inch shackle, galvanized ring (for convenience), and a 5 foot pennant with stainless snap.

I replace all the metal and nylon every three years – with the exception of the 1-1/2 inch safety shackle, which seems to last 15 years, more or less. One could argue that the swivel should be at the top of the rope so the bottom shackle could stand vertical. This might be a better setup, but I’m worried about wearing out the anchor ring. Once that’s gone, it’s game over.

The “upper swivel” setup would look something like this:

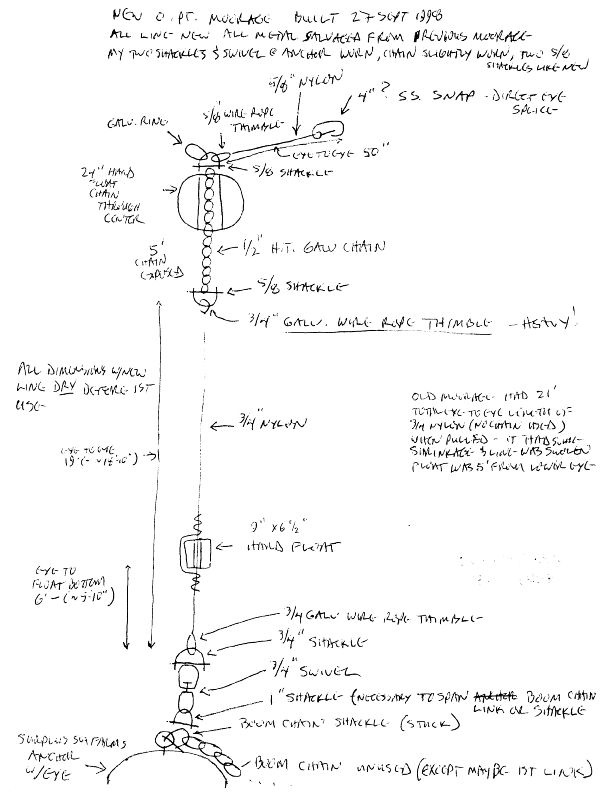

The original sketch:

The original sketch:

And what the 2016 version looks like:

A cleaned up schematic:

Mooring ReDraw 2020.05